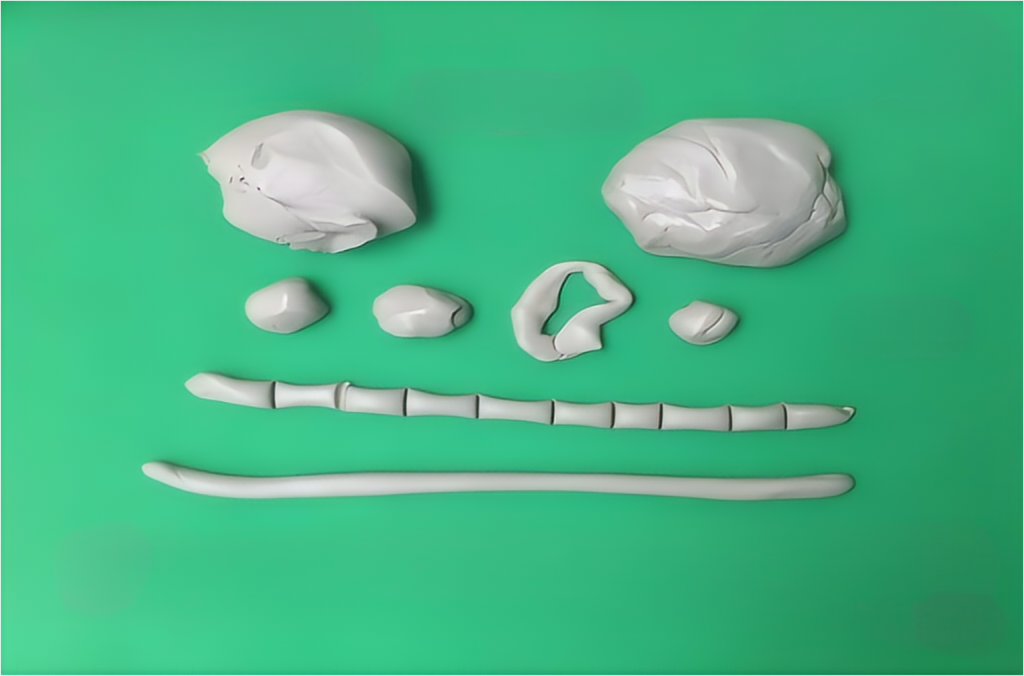

1. Appearance: white semi collapsed shape. 2. Excellent adhesion to power substrate aluminum, copper, wire, and plastic 3. Waterproof and moisture-proof, excellent electrical insulation performance, protecting components from mechanical vibration and external impact 4. Flame retardant performance reaches UL94 V-0 level 5. Through international environmental protection Rohs and EU Reach certification