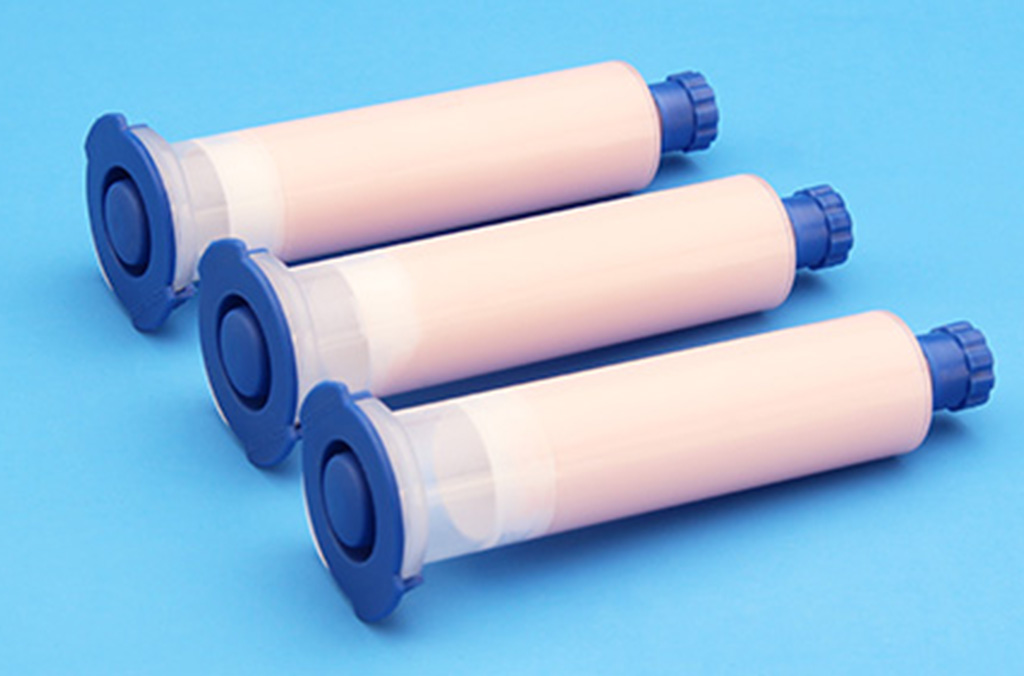

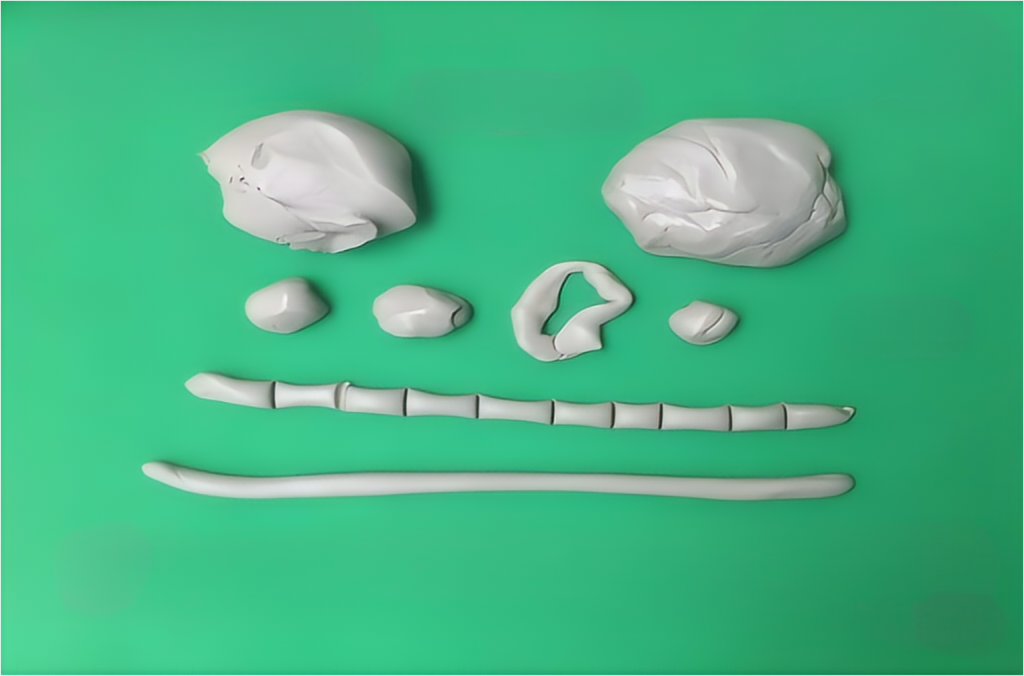

Thermal conductive sealing adhesive is a two-component silicone adhesive used as the base material, with a certain proportion of heat-resistant and flame-retardant additives added, and cured to form a thermal conductive sealing adhesive. It can reliably protect sensitive circuits and components in a wide range of temperature and humidity changes for a long time, and also has certain characteristics such as earthquake resistance, fall resistance, and dust prevention