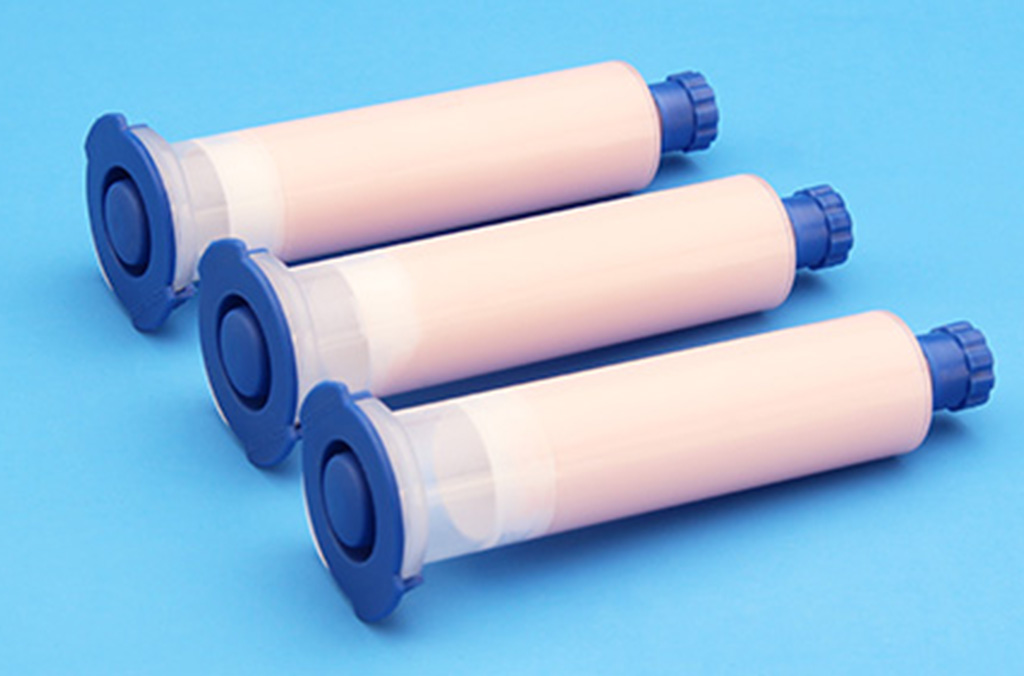

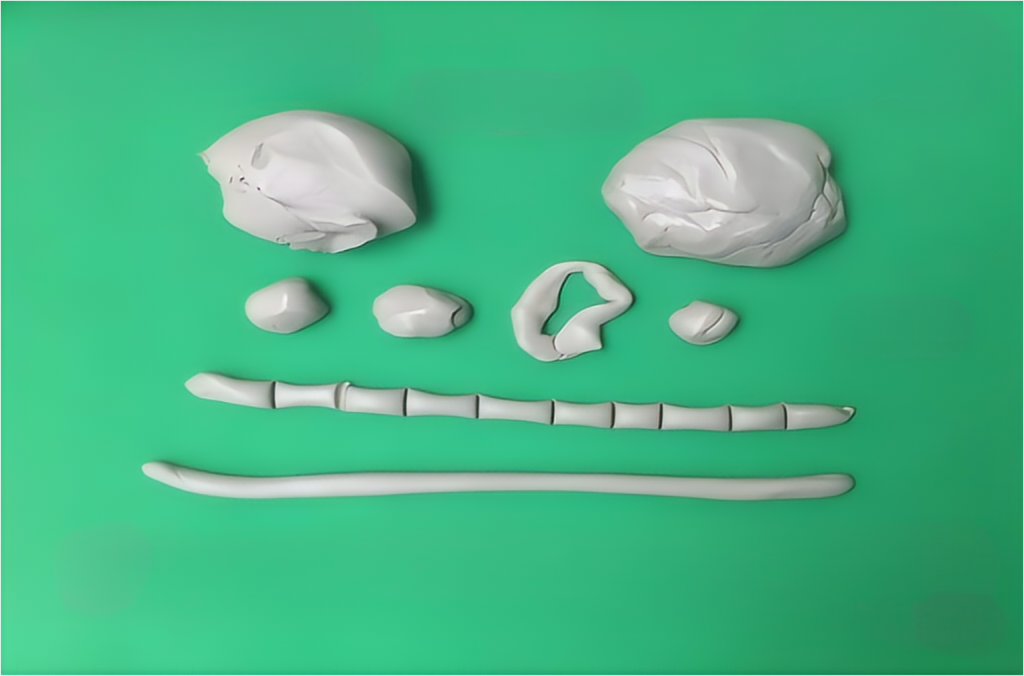

Thermal conductive gel is a two-component thermal conductive silica gel product, which mainly meets the requirements of low stress and high compression modulus when the product is used, and can realize automatic production; Has good contact with electronic products during assembly, exhibiting low contact thermal resistance and good electrical insulation properties. The cured thermal conductive gel is similar to the thermal conductive gasket, with good high temperature resistance and aging resistance, and can work at -40~180 ℃ for a long time